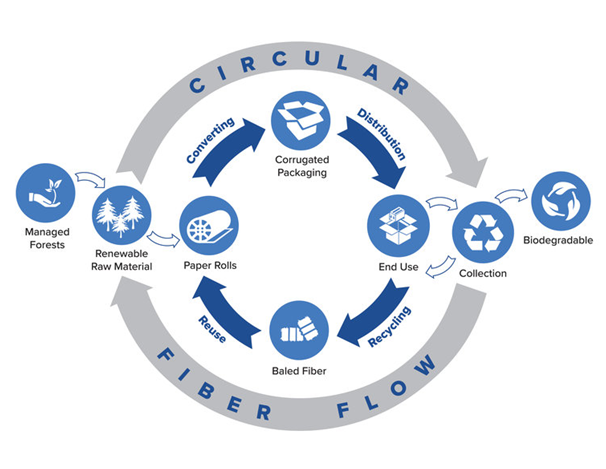

Corrugated cardboard boxes being affordable, versatile, provides excellent structural stability for shipping, storing, and marketing product. And at the same time its environmentally friendly. Corrugated packaging is generally considered the most economical type of packaging. Custom printed boxes are an inexpensive and effective way to enhance your company’s brand, attract attention, and grow awareness.

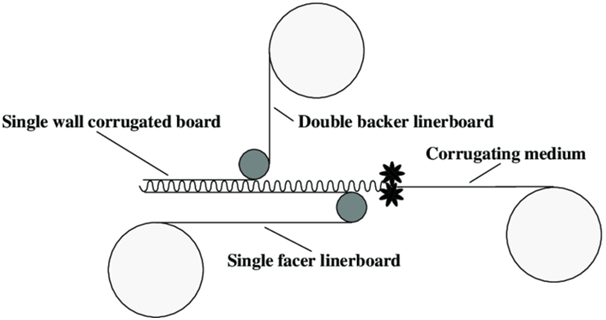

Single wall corrugated consists of one layer of fluting (also referred to as medium) in between two layers of linerboard. Double wall corrugated consists of two layers of fluting and three layers of linerboard. The 5-py construction offers a great deal of strength and extra padding for especially heavy or fragile items.

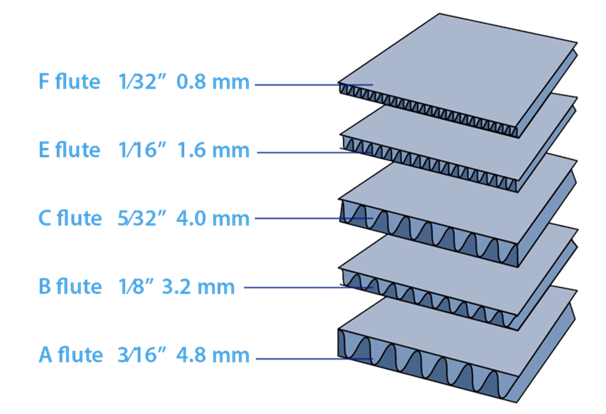

Fluting is simply the wavy looking paper that is sandwiched between the two linerboards that gives corrugated boxes its strength and protection attributes. Different flutes are combined when making a double wall box to take advantage of their different properties.

Corrugated packaging is extremely versatile and can come in various shapes and sizes to meet almost any shipping need.In order to start the design process, we first need to understand the shipping environment and risk of product damage. For more fragile products, we can help design a corrugated box with maximum protection to ensure your products arrive safely. For less fragile products, we can change our focus to operational efficiencies and overall cost reduction.

We are able to print the several colours boxes and add your business logo, name, tagline, or any other identifying information on the box.

Below are a couple of examples of the most popular corrugated boxes. We have the technology and tools to create anything you can imagine.

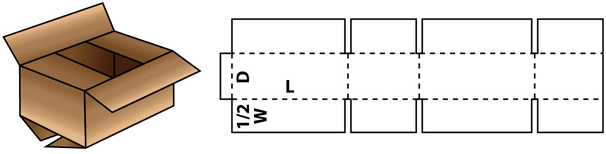

REGULAR SLOTTER CONTAINER

The Regular Slotted Container (RSC) is the most common box style used for shipping and storage. The two outer flaps of an RSC box meet at the centre of the box when folded and are usually closed using tape or staples.

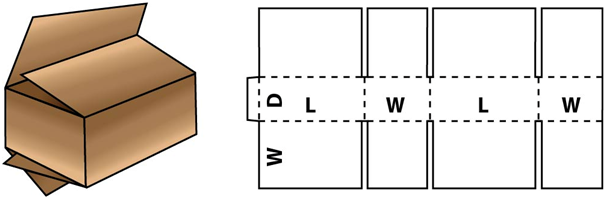

FULL OVERLAP CONTAINER

The Regular Slotted Container (RSC) is the most common box style used for shipping and storage. The two outer flaps of an RSC box meet at the centre of the box when folded and are usually closed using tape or staples.

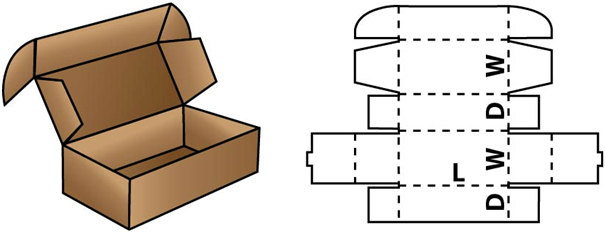

DIE CUT FRONT TUCK SHIPPER

Die cut shippers require special tooling (referred to as cutting dies) to be manufactured. Different options are available depending on the project. The most common option is the front tuck shipper. This is a versatile shipping box that provides great protection. After the boxes are cut, they can be further customized by adding unique graphics or inserts to present the product.

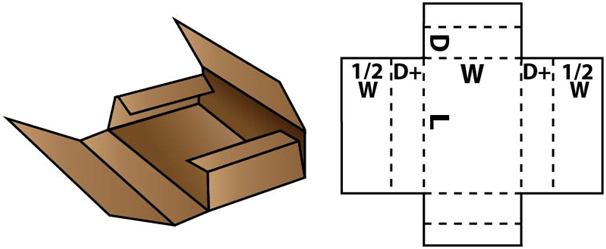

ONE PIECE FOLDER

The One-Piece Folder (OPF) box is an ideal shipper for flat items with shallow depth such as books, marketing kits, and other media. This style features a single piece of corrugated with a flat bottom, end flaps, and side flaps that fold over and meet to form the top of the box.

FULL TELESCOPIC DESIGN

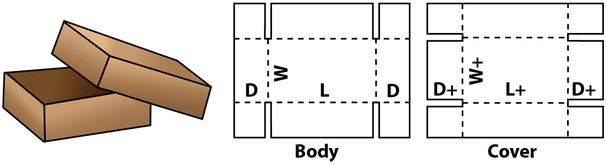

FTD cartons consist of a separate top and bottom that fit over each other with flaps joining on the side or end panels. When pulled apart, they create two scored and slotted trays, both with flat bottoms. The full-depth cover slides completely over the body of the carton providing additional strength around the sides making this style suitable for high stacking strength of fragile articles.